What’s been happening?

Well I failed at posting once a month, my bad. A lot has been going on since March.

I’ve been talking to the new owners of Modal Electronics on and off, since September, and I just stepped away from it. My reasons? There are a few, but mostly because their vision and what I am passionate about in synths are very different things. There were a number of other factors involved, but I won’t go into them.

I’ve also not been well, for the couple of weeks I’ve been having major chest pains that come and go, a few days ago I ended up in an ambulance on my way to A&E as I was struggling to breath and had number fingers and leg (both left hand side). Thankfully it wasn’t a heart attack and a number of other things have been ruled out, but we don’t yet know what the problem is. I still have a painful chest and breathing is not easy.

So I’ve been taking it easy and giving myself plenty of time to rest, this has meant synth things have slowed down considerably.

In other news, I did get myself a Roland system 100m, which sounds wonderful. I’ve had to clean up some of the modules (sticky pots and bad sockets) and the keymech also needed a good clean, as well as fixing a broken sample and hold (bad FET) and all is now good aside from two sockets.

I’ve wanted one of these since I saw them with the band “landscape” in 80s keyboard magazines and also when I saw “Hard Corps” on “The Tube”. It’s an amazing sounding synth and feels really solid, I mean the front panels are CNC machined metal!

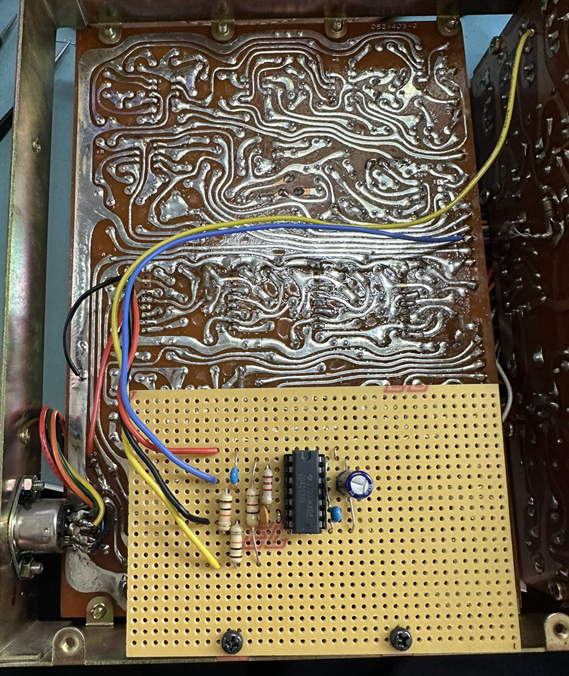

Anyway, after playing with it for a few weeks I wanted to beef up the sound, so for each of the 110 synth voice modules (VCO, VCF & VCA) I added a sub oscillator which is normalized to the 2nd input on the VCF mixer. No holes were made and no tracks were cut, it needs 4 wires soldering on and it fully reversible.

Even the frame supporting the PCB has M3 holes pre-tapped, so I was able to secure the PCB in place. It makes a huge difference to the sound, which takes me back to my childhood. Here is a video from my Mastodon account – https://files.mastodon.social/media_attachments/files/112/609/534/481/076/967/original/9f0e4b6705933889.mp4

I’ve looked at doing some modules for the 100m, but owing to the complexity of the CNC front panels, I’m not sure I can. Ryk-Modular and E-Licktronic do some modules for the system, so maybe there would be a way to work with them in the future?

I have also been tinkering with the 8×8 display I made, and I’m having a problem getting it to respond quickly enough to work with my PDP11 board. The main problem is that the write signal is around 500nS wide, and currently it’s taking the 8×8 display chip (ATMega1609) 670nS to respond to the falling edge interrupt! This is after I’ve tried two different compilers and optomised the heck out of the code. It *should* respond in about 5 clock cycles according to the datasheet, which is around 250nS, but I suspect the C compilers aren’t very efficient, so I may have to move to assembly language, or find an alternative processor, which I’d rather not have to do.

But for now, I’m still taking it easy.